Our Company

Founded in 1958, Yangzhou Metalforming Machine Tool Co., Ltd (YADON) has now

become a subsidiary of Schuler Group. Besides, YADON is in the lead of providing automatic

stamping solutions, including transfer line, multi-station press line, and multi-machine line.

Over the past decades, YADON has obtained the core competitiveness of high efficiency,

stability, precision and low-cost production by satisfying customers' strict requirements with

high-quality products and service.

Company Video

We have been specializing in R&D, manufacturing and selling of forming

machines, covering mechanical press, high-speed press, die forging presses, powder forming

machines, fine blanking machines, press remanufacturing and etc.

View Video

View Video

Our Product

Hot Product

YSH Straight Side High-Speed Three-Point Press Line

Model of innovative design by Japanese team;

Machine tool that exceeds JIS-B-6402 precision;

Three-point drive long slide;

Separated structure and high rigidity cast-iron frame;

Four-column high-rigidity cylindrical linear bearing guide;

Dynamic balance system, low vibration and low noise;

hydraulic locking device for adjustment rods, ensuring the precision of bottom

dead center;

The adjustment precision of die set height is 0.01mm;

Accurately control the precision of bottom dead center by using forced

lubrication, temperature automatic control system and thermal compensation

technology;

Integrated touch screen control interface.

J76 Series Straight Side High-Speed Two-point Precision Press Line

Two-section split-type structure and high-strength cast iron frame ;

High-strength Eccentric alloyed steel crankshaft;

imported bearings and Four-point crankshaft supporting structure (80-300T);

Slide is guided bu linear clearance- free ball bearing plunger bushes (80-300T);

Dynamic balance system, low vibration and low noise;

Low-inertia big-torque pneumatic clutch brake unit;

hydraulic locking device for adjustment rods, ensuring the precision of bottom dead center ;

Accurately control the precision of bottom dead center by using forced lubrication, automatic temperature control system and thermal compensation technology;

Programmable cam controller;

Integrated touch screen control interface;

YPH Motor Lamination Progressive Line (Big Size Motor)

High-rigidity H-type frame composed of separable crossbeam, uprights and basement;

Six-point type, high-strength dynamic pressure crankshaft supporting;

High-strength double eccentric crankshaft with good synchronization;

High-precision8-side long guide rail;

The hydraulic locking device for adjustment rods, ensuring the precision of bottom dead center;

Hydraulic overload protection device;

Forced automatic oil cycle lubrication system.

YKC Series H-type Fin Press Line

Components: Uncoiler, oil tank, pneumatic initial feeding, straight side high-speed precision press, suction device, stacker device, electrical control system, air system, hydraulic system;

Main motor speed and vacuum suction cup are controlled by frequency converter;

Slide is provided with hydraulic lifting function for easy die installation and commissioning;

With protection functions such as material collection error, oil-free alarm and material-free detection;

Hydraulic overload protection device, to protect the main machine and die, convenient use;

Quick die changing device, to achieve more convenient and fast die changing;

Grease circulation lubrication system with oil circuit alarm function, to ensure the smooth operation of machine tool;

PLC electrical centralized control system ensures the execution of various functions of the production line, human-machine interface and easy operation;

Optional: automatic waste e-jet device.

JL21 Series C-type Frame High-Speed Press

L21 seriesC-type frame high-speed production line is specialized for fin production in the refrigeration industry. It consists of uncoiler, oil tank, press machine, vacuum suction cup and a collecting device;

PLC electrical centralized control system, encoder, pre-set counter, cutting counter and aggregate counter that meet the requirements of high-speed production lines, as well as function of progress change;

The main engine is equipped with hydraulic overload protection and die height motorized adjustment device (except JL21-45B);

Automatic oil circulation lubrication system with circuit alarm function.

MP Series Hot Forging Press

400T - 2500T adopts split steel welded body, 3150T - 6300T split cast-iron body, MP (B) adopts integrated cast body;

with high inertia flywheel and high output energy, so it is suitable for hot forging and forming;

With double-pivot link and extended guide rail and strong resistance to offset load, it is suitable for multi-station forging, and it can form an automated forging production line with progressive arms or robot;

Fast slider speed, short touching time between die and work pieces, which can prolong the service life of die;

“X”-type guide rail, and the thermal sensitivity of gap between guides is low;

Shut height adjustment is motorized and digital display the height;

Clutch and brake are equipped with floating insert pneumatic friction structure;

-

J76 Series Straight Side High-Speed Two-Point Precision Press Li

-

JB36-500 Motor Housing Multi-Station Stamping Line

-

MP Series Hot Forging Press

-

YPH-400 Motor Punching Production Line

-

YPH-550 Motor Punching Production Line

-

YPM-500 Motor Housing Multi-Station Stamping Line

-

YSH-400 Closed Three-Point High-Speed Precision Press Line

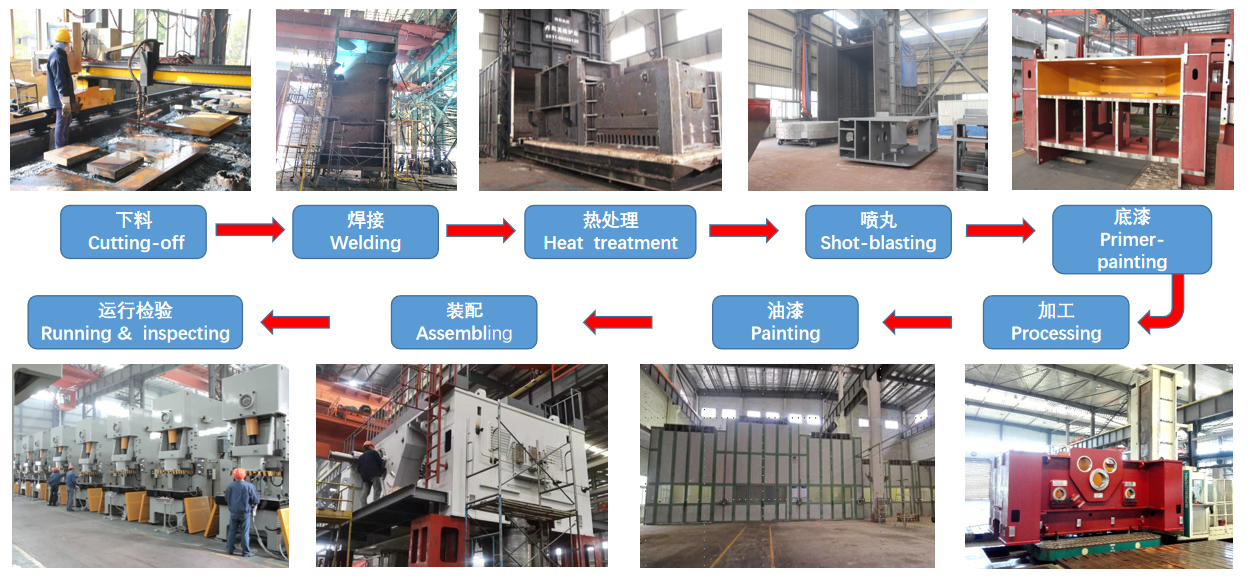

Process Control

-

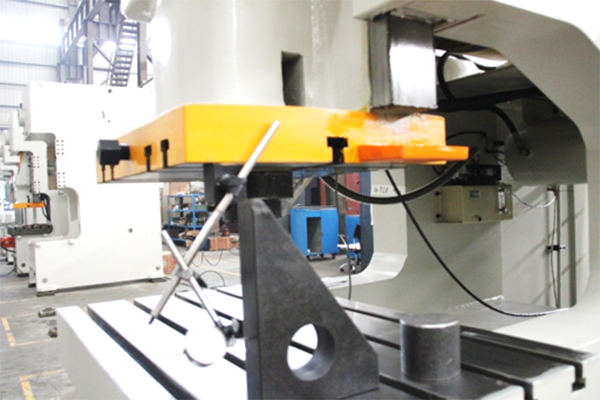

Process control-Assembly

Process control-Assembly

-

Process control-Assembly

Process control-Assembly

-

Process Control-Inspection

Process Control-Inspection

-

Process Control-Inspection

Process Control-Inspection

-

Process Control-Inspection

Process Control-Inspection

-

Process Control-Inspection

Process Control-Inspection

-

Process Control-Inspection

Process Control-Inspection

-

Process Control-Inspection

Process Control-Inspection

-

Accuracy

Accuracy

-

Noise

Noise

-

Simulation Experiment

Simulation Experiment

-

Load Test

Load Test